Why a SIPOC process model is best suited for cause and effect as well as scenario analysis ?

The SIPOC process modeling notation supported by the ProcessHorizon web app provides a structured and visual representation of a process, making it well-suited for cause-and-effect analysis and intervention scenarios.

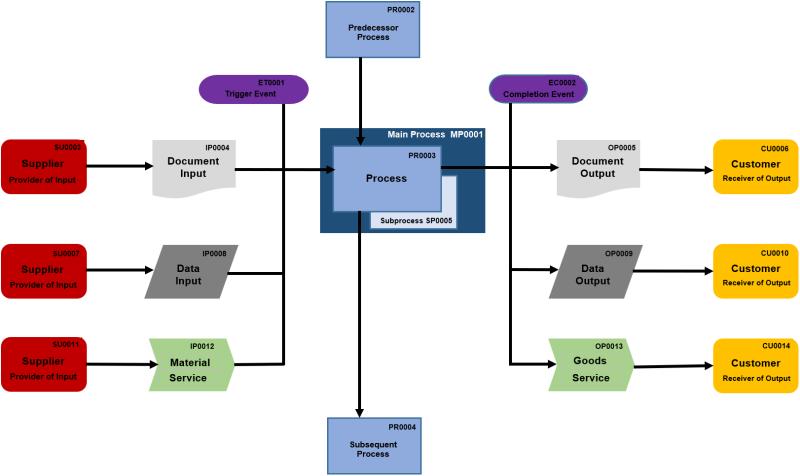

SIPOC causal diagram:

Suppliers => Inputs => Process => Outputs => Customers

1. Clarity of Process Flow

- Reasoning for Cause and Effect: The SIPOC process model inherently outlines the sequential flow of a process, making it easy to identify cause-and-effect relationships. It shows how inputs from suppliers influence the process, leading to specific outputs that impact customers.

2. Identification of Critical Elements

- Explicit Representation: The SIPOC process model explicitly represents key elements of the process, such as suppliers, inputs, and outputs. This clarity helps in identifying critical factors that contribute to the overall performance of the process.

3. Causal Relationships

- Process-Driven Causality: The sequential nature of the SIPOC process model implies causal relationships between elements. Changes in suppliers or inputs are expected to cause changes in the process, subsequently affecting outputs and customer satisfaction.

4. Intervention Points

- Natural Intervention Points: The SIPOC process model highlights specific points in the process where interventions can be made. For example, if an issue is identified in input quality, interventions can be designed to improve supplier quality or modify the input specifications.

5. Counterfactual Scenarios

- Effective Use of "do" Notation: The SIPOC model, coupled with Pearl's "do" notation for interventions, allows for counterfactual scenarios. Analysts can use this notation to assess how changes in specific elements like e.g. process efficiency or input quality would influence the overall process and outputs.

6. Systematic Cause and Effect Analysis

- Structured Approach: SIPOC process model notation provides a structured framework for cause and effect analysis. By systematically examining each element in the process, analysts can uncover potential sources of variation, identify root causes of issues, and design targeted interventions.

7. Communication and Collaboration

- Visual Representation for Stakeholders: The visual nature of SIPOC process mapping makes it effective for communicating complex processes to stakeholders. This shared understanding fosters collaboration in cause-and-effect analysis and the design of interventions.

8. Holistic View

- End-to-End Perspective: The SIPOC process modeling architecture supported by the ProcessHorizon web app offers a holistic view of the process flow over three process layers as needed. This comprehensive perspective helps in understanding the full causal chain and considering the broader implications of interventions.

The SIPOC process model augmented by the trigger and completion events represents a chain of causation with each element bound together as cause and effect. An action causes an effect and the chain is the unbroken link between action and effect.

Explore the smart ProcessHorizon web app for holistic automated process & data mapping AllinONE: https://processhorizon.com