End2End Process Cycle for Lithium Car Batteries

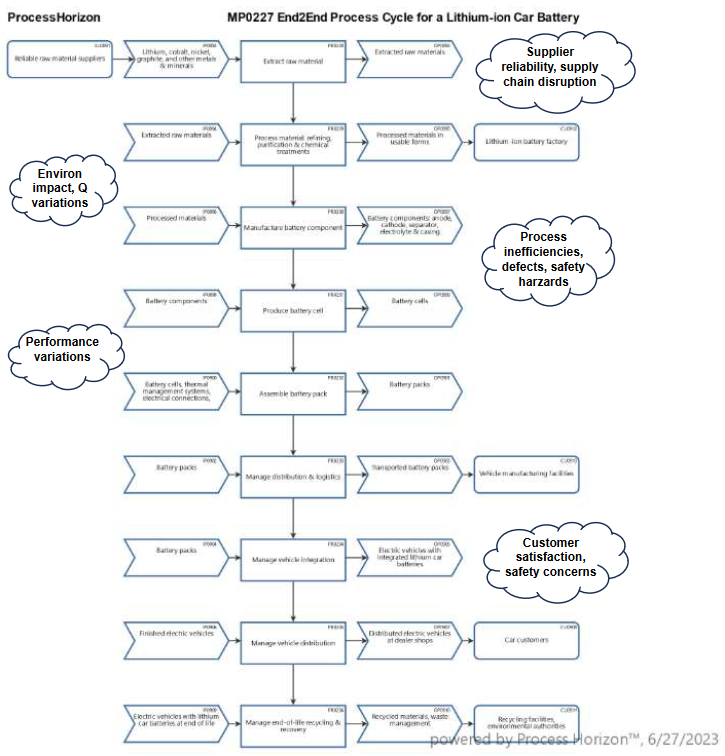

The end-to-end process cycle for a lithium-ion car battery involves a series of events and processes from the initial production of the battery components to the final installation in an electric vehicle (EV).

- Raw Material Extraction: The supply chain begins with the extraction of raw materials required for lithium-ion battery production. These materials include lithium, cobalt, nickel, graphite, and other metals and minerals.

- Material Processing: The extracted raw materials undergo various processing stages, such as refining, purification, and chemical treatments, to obtain the necessary materials in the desired form.

- Battery Component Manufacturing: The processed materials are used to manufacture different components of the lithium-ion battery, including the anode, cathode, separator, electrolyte, and casing. Each component undergoes specific manufacturing processes, such as coating, stacking, and assembly.

- Battery Cell Production: The battery components are assembled to form battery cells. Battery cell manufacturers utilize specialized equipment and techniques to ensure the precise construction and performance of the cells.

- Battery Pack Assembly: Battery cells are then combined into battery packs, which are responsible for providing power to the electric vehicle. The pack assembly includes the arrangement of cells, thermal management systems, electrical connections, and safety features.

- Distribution and Logistics: Once the battery packs are assembled, they are transported to distribution centers or directly to the vehicle manufacturing facilities. Efficient logistics and transportation networks play a crucial role in ensuring timely delivery.

- Vehicle Integration: At the vehicle manufacturing facility, the lithium car batteries are integrated into electric vehicles as part of the production process. This involves the careful placement of battery packs, electrical integration, and compatibility testing.

- Vehicle Distribution: The electric vehicles, now equipped with lithium car batteries, are distributed to dealerships or directly to customers. This stage involves coordination between vehicle manufacturers, distributors, and transportation companies.

- End-of-Life Management: As the batteries reach the end of their useful life in the vehicles, proper recycling and disposal processes are essential. Battery manufacturers and recycling facilities work together to handle battery recycling, aiming to recover valuable materials and minimize environmental impact.

Throughout this end-to-end process cycle, various events can impact the process, such as changes in raw material availability, production delays, transportation disruptions, and advancements in battery technology. Effective supply chain management and coordination among all stakeholders are vital to ensure a smooth and efficient flow of lithium car batteries from production to end use.

Explore the smart ProcessHorizon web app for automated process mapping and design: https:processhorizon.com